Partnering with engineers to create the highest quality products

Customization that is built to last

Trystar designs and creates power distribution equipment; cable and generator docking stations are manufactured at a state-of-the-art facility in Faribault, Minnesota. Creating tailored products for a multitude of industries and companies is their bread and butter. Trystar is an expert at designing products but needed help creating them to meet demand. That is where Foundry stepped in to help.

PROBLEM

Trystar needed to keep up with the demand for their products. Trystar's previous system was time-consuming and slow. They had the demand but lacked the infrastructure.

SOLUTION

Foundry created apps to tackle every step of Trystar's operations and systems. We talked to every department to come up with a cohesive product that has streamlined their process.

RESULT

Foundry created an efficient and optimized way to create products for their customers that saves Trystar time and money. Streamlining the way that they create products.

High Voltage to Mix & Match

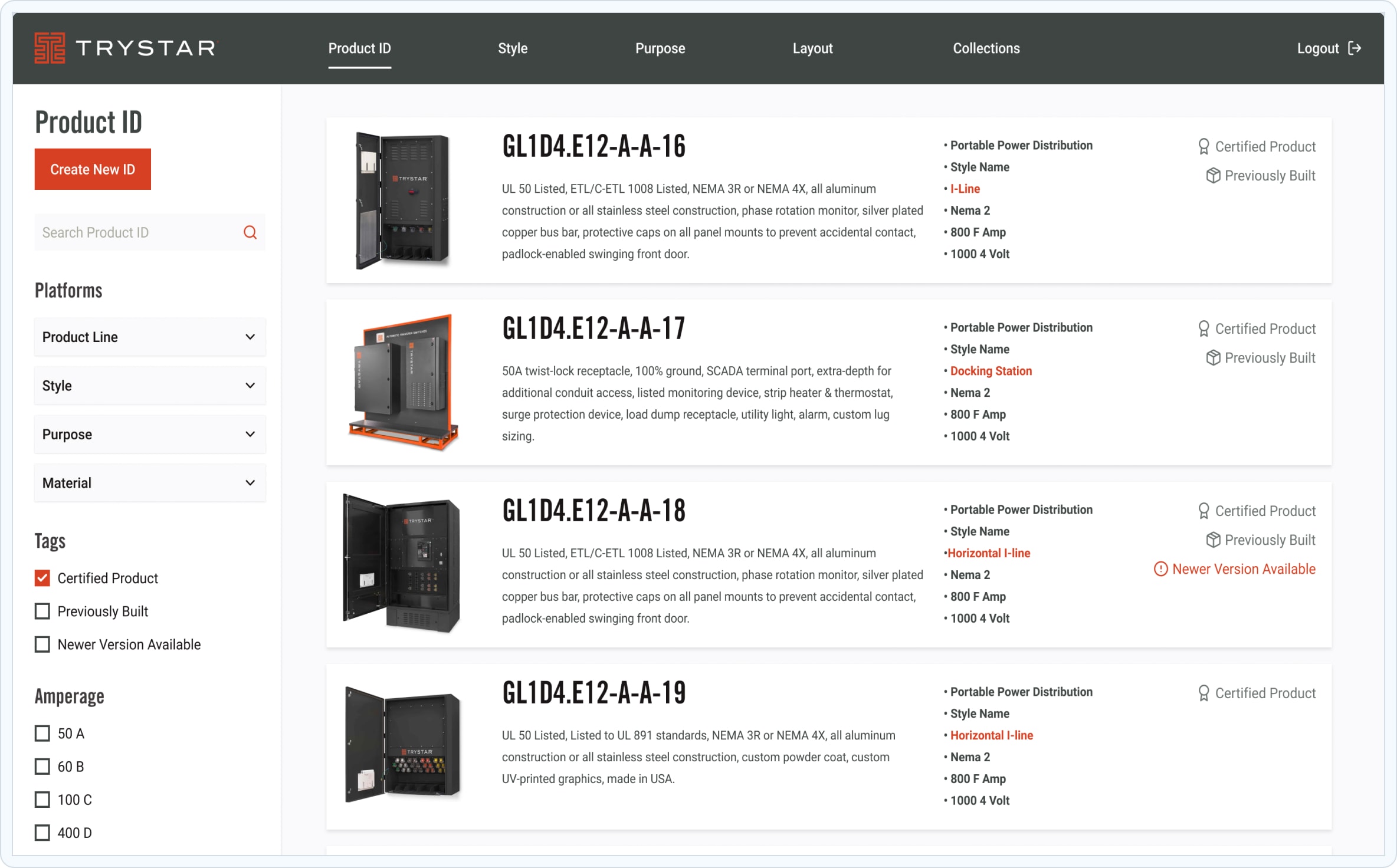

At first glance, it might look like Trystar makes a small selection of about a dozen products. However, to serve the specialized technology needs of their customers, each of these product lines has a dizzying array of possible configurations. Voltage, amperage, material, receptacle types—even the color is customizable. Each rugged enclosure is a blank canvas for literally hundreds of possible permutations.

Defining Complexity, Easily

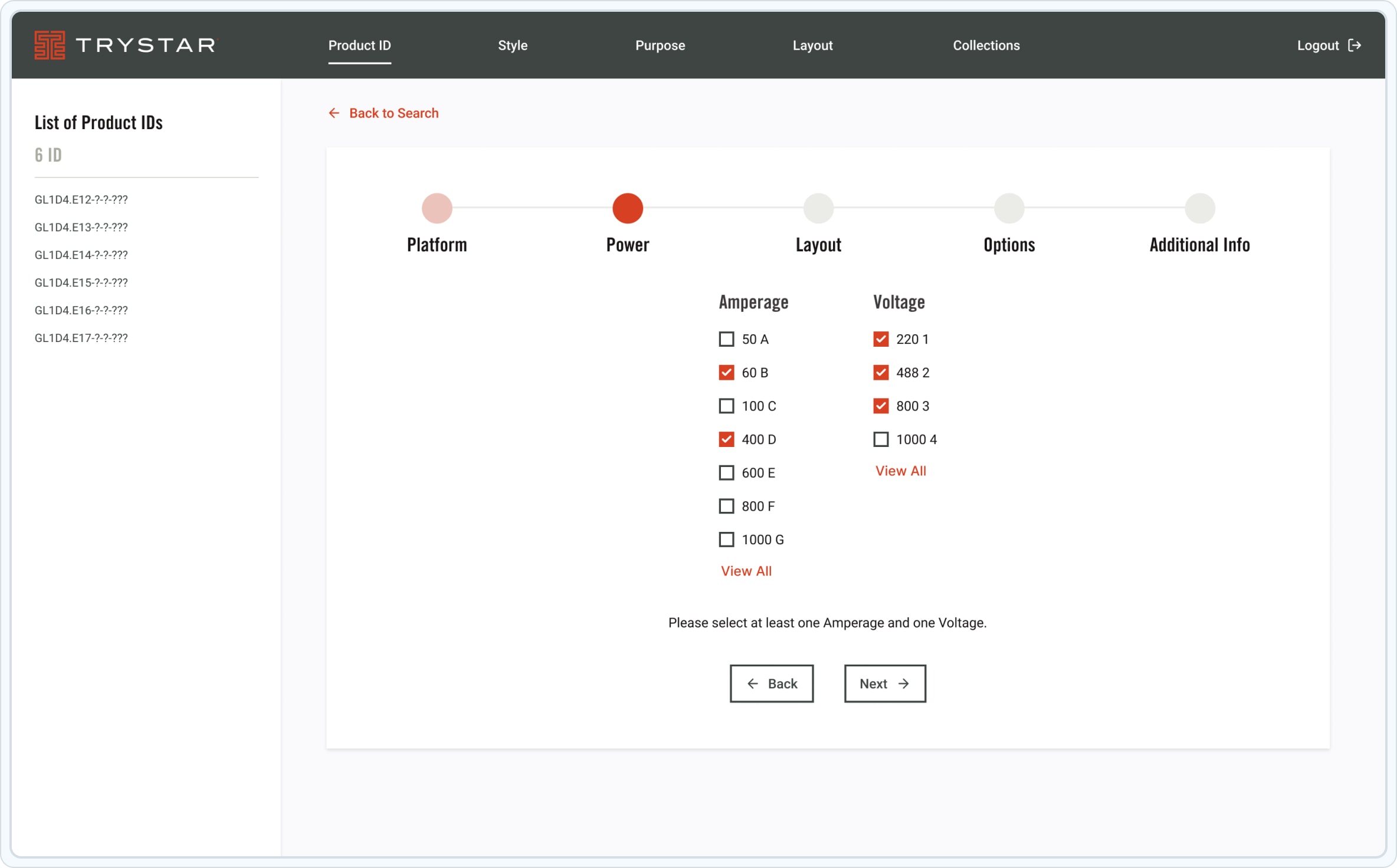

Working closely with Trystar’s team to understand all the fine points of their workflow, we designed and built a powerful system for classifying and documenting every product their engineers can dream of. In a simple series of steps, an engineer can define the parameters of a new product line, attach relevant diagrams, and automatically assign a unique product ID to each potential permutation—even ones that haven’t been built yet. In addition, “versioning” enables engineers to make updates to a model down the road without breaking from a consistent numbering system.

Profile of a Product

Instead of tracking mix-and-match feature scenarios through endless spreadsheets, Trystar’s engineering team needed a consistent system of classification so they could document each build and easily repeat it in the future. The sales team needed a better way to understand which permutations were possible and which had already been built.

Trystar & Foundry

Strategy

Product Workshop

Feature Prioritization

Insights Documentation

Design

UX/UI Design

Prototyping

Visual Design

Development

React

NestJS

TypeScript